This story is a product of Heavy Table’s first Listening Session, underwritten and hosted by the Lakewinds Food Co-op. On May 23, we interviewed 15 local food artisans over the course of eight hours, with a goal of taking a snapshot of the vibrant Minnesota food scene.

When a proper history book about the evolution of Upper Midwestern food gets written (probably in about 100 years), no doubt the region’s thriving food co-op scene will be near the center of the story. Minnesota (and neighboring states) have been waking up from a culinary inferiority complex and tapping into the rich resources at hand — farms, lakes, forests, and people — to create food that is legitimately local, and has a profile that no other part of the country can lay claim to. By binding together farmers, artisan food producers, and consumers who are looking for something one or two steps beyond the mega-market food experience, co-ops are carrying the flag for the region in a way no other force really can.

Case in point: Lakewinds Food Co-op. Lakewinds is using a new program called Maker to Market to incubate, advise, and help launch small food producers by transitioning promising makers from home kitchens to professional production and distribution.

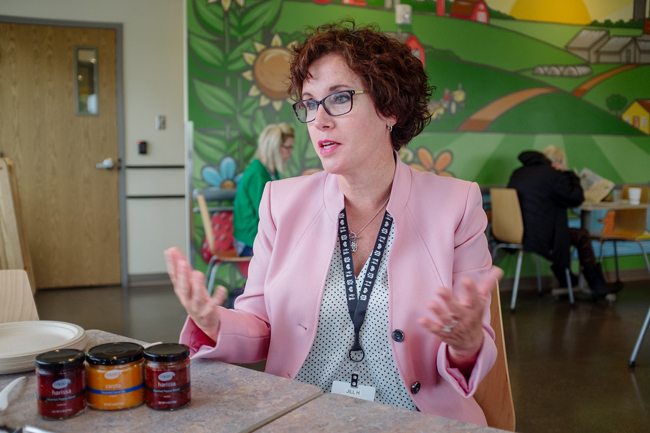

“We do great in the produce department and our house-made deli, but at the center of the grocery store, we’re always looking for new local products,” says Jill Holter, the media and community outreach specialist for Lakewinds. “We cooked up this scheme using The Good Acre‘s farmer network and kitchen space. We would offer our branding and retail packaging and pricing knowledge, and knowledge of where we see gaps [in the market].”

“We put an application online, and we got 30 applicants,” says Holter. “For local food makers to break into retail requires distribution, and it requires packaging help. And it requires the ability to analyze their costs and make their margins.”

The first part of the process was sorting through all the applicants, a process that was driven in large part by taste.

“We put together a great big panel of people across the food world … and we sat down and tasted absolutely everything. We had a big day and were pretty full at the end. We looked at their stories and talked about their products, and our main focus was ‘Is this produce-heavy?’ We wanted to source ingredients from The Good Acre’s farmer network. We weren’t going to do granola — we have enough granola at the co-op — and we got lots of submissions for baked goods and other products that weren’t right for the program, but they were good products and good people. So what we chose were salsas and harissa and carrot dip and traditionally fermented pickles.”

The program starts out with a consulting session with each maker to examine ingredient sourcing, costs, packaging, and other essentials.

“We start with what they have, and help them get up to speed on sourcing, packaging, and branding so we can make our margins and they can make a profit, too,” says Holter. “And then we get them into The Good Acre kitchen and they start producing, and they learn how to incorporate labor costs. We are comping their kitchen time for the first three months, and then [their share of the payments] will be gradually increased. Each month we’re giving them an invoice with a zero dollar balance at the bottom that breaks out retail consulting, branding consulting, kitchen space, storage, distribution … because when they leave our six-month program (which we want them to do — we want them to sell at the Wedge or Whole Foods or wherever they can be successful) we want them to know what their costs are going to be. Because if we incubate them to such a degree that they don’t have to plan, after six months they won’t be successful.”

By building a stable of sustainable, local-artisan food businesses, Holter says, it’s a win for consumers, the co-op, and the producers themselves. “If we can have classes of graduates every year, then we’ll know we’ve been successful,” she says. “As this becomes more successful, I know there are makers out there who will see this and want to get involved.”

The first round of Maker to Market products includes:

Harissa, Smoky Harissa, and Carota carrot dip from the husband-and-wife team at Caldo Foods — all three products have a powerful depth of flavor, and the harissas in particular are versatile and punchy, perfect for accentuating grilled seafood such as shrimp or blending with mayonnaise to create a next-level sandwich spread. The carrot dip (which is to say, dip made from carrots, not for carrots per se) is fresh, delightful, and light.

“At a co-op, people will pay more for local if it’s made from great ingredients and there’s a great story behind it,” says Holter. “Like harissa: They might not know what to do with it, but if they know it’s made here in Minneapolis by great people, they’ll try it.”

Caldo Foods: Traditional Harissa, 6 ounces, $12; Smoky Harissa, 6 ounces, $12; Carota, 12 ounces, $9

Gyst Fermentation Bar has made a name for itself in the local food community, putting forth sophisticated tastes at its Eat Street-proximate restaurant and tapping into a growing enthusiasm for all things (bacteriologically) cultured. Both the beet and the radish pickles by Gyst were funky and earthy as opposed to spiced or sour in a conventional dill pickle sense. They each had their own powerful, pungent aroma that was followed by a subtle, multilayered flavor that embraced the natural taste of the base vegetable while adding depth.

“[Gyst] is a fun business to have in this program because they have retail experience and a real intimate knowledge of the food culture in the Twin Cities,” says Holter. “And it’s two really smart, interesting women. Sometimes all four makers will be in The Good Acre kitchen at the same time, and it’s great to hear them talking — ‘Oh, let’s try this salsa on the pizza,’ or ‘would these daikon radish pickles be good with. …’ And there’s a camaraderie among the makers — and Gyst, who have been in the business for a while, can offer a lot of experience to share.”

Gyst: Golden Beet with Orange and Ginger, Daikon Radish with Chili, each: 9 ounces, $9

The smoothly blended salsas of Señoras de Salsa are mellow and full of flavor, with the guajillo bringing a pronounced smoky flavor to food and all three varieties offering serious depth of flavor without leaning on the crutch of intense, spicy heat.

Señoras de Salsa: Guajillo Mild Salsa, Chipotle Medium Salsa, Salsa Verde Medium, each: 9 ounces, $7

Cheese worked into the crust is part of the solution that Little Red Hen Foods offers to the problem of gluten-free, cauliflower-based pizza crusts tasting too strongly of their constituent vegetable. Mission statement notwithstanding, cauliflower comes through pretty clearly in this pizza — a heavier, spicier sauce and/or more aggressive toppings on future iterations might help balance it out or shout it down. In its current form, this is a gluten-free pizza that will be a true treat to cauliflower fans.

Little Red Hen: 10½″ Cauliflower Crust Cheese Pizza, 12.8 ounces, $12