After having a long and successful career that culminated in his building the New French Bakery into a large-scale food business, Peter Kelsey was out of challenges. “I sold the bakery almost out of boredom,” he said. “The business had gotten really big. There were no new problems to solve.” Thus K’ul Chocolate was born.

Kelsey’s retirement lasted a whopping four days, during which the now-ended boredom at the New French Bakery turned into boredom at having no other work on hand. As an avid biker, he had also become frustrated at the state of energy bars. He didn’t want a bar full of granola or oats, something he says can be very hard to chew when you’re thirsty. What he really wanted was chocolate, high-quality chocolate, chocolate bars that could double as functional foods. “I wanted beans with benefits,” he said.

He also wanted to handle the whole process. “I looked around and found that someone wanted to co-pack, someone else wanted to make the chocolate,” Kelsey said. “But I wanted to do it all from scratch.”

That included sourcing everything himself to get the complete farm-to-bar product that was his goal. “I’ve been to Brazil, to Haiti, to Ecuador,” he said. “I work with farms or co-ops. The farms are very small, and they only produce hundreds of pounds of beans each year, when it needs to be shipped in the tons. That’s where the co-ops come in. It’s similar to some coffee bean purveyors.”

Working directly with providers allows Kelsey to achieve another goal — keeping the bars reasonably priced by not having middlemen involved. “I really believe in making great food affordable,” he said. “The bakery was originally born because I was tired of making food people couldn’t afford.” But that can also mean trade-offs. “You see some of these farmers who are growing organically out of necessity, because they can’t afford fertilizers or pesticides. They could grow twice the quantity of hybrids, but the chocolate purists don’t want that. It’s hard to tell a guy who’s making $2,000 a year not to grow hybrids. It’s disingenuous in a naive way to look for organic, non-GMO, fair trade, and think it’s the right thing to do to the exclusion of thousands of people growing chocolate outside large corporations.”

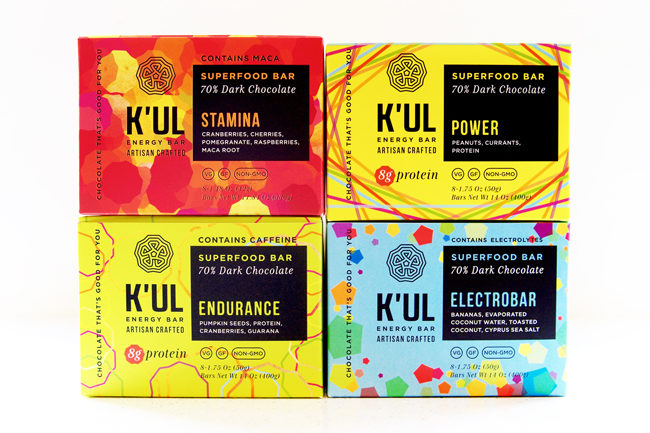

For the most part, Kelsey isn’t using hybrids, although he makes exceptions in some cases when the quality of the product isn’t reduced and it helps keep the price down. The bars run $3-$4.50 each, and $25 or $30 for a box of 8-12 bars. “Basically it’s a free bar per box,” Kelsey said. The company name, K’ul, comes from the Mayan word for “energy.”

Kelsey’s first line took nearly two years of development before it was ready to go, midway through 2015. The time included a stint in the basement lab of a guy who used to work for Guittard. Then Kelsey set up shop in a former karate studio on Franklin Avenue along with experienced chocolatier James Palmer. It turned out that researching sources of top-notch beans was just a precursor to finding all the equipment he’d need to turn those beans into finished, packaged bars. The production floor includes a Danish seed-cleaning machine, an Austrian de-stoner, and a Brazilian winnower, among other imports.

But in the end, Kelsey gets his raw beans, cleans and stones them, then roasts them for 40 minutes at exactly 248 degrees — usually. “That can change based on the lot [of beans],” he said. “We have to learn how each type of bean needs to be handled.” The roaster was specifically built for cacao beans. “They’re very delicate and can’t be handled by a coffee roaster,” Kelsey said.

After the beans have cooled, they’re broken up to pull the shell off and put through a vacuum machine to separate the shells from the cacao pieces. Then they’re ground. “It’s all stone-ground,” he said. “It’s an ancient technology that’s been used for millennia. The Mayans used basalt stone slabs with basalt rolling pins, and that’s not so different from what we’re using.”

The grinder agitates at 750 RPM and grinds up the chocolate into particles of under 20 microns. “We try to keep ours under 18 microns, “Kelsey said. “Lindt runs 18-20, Godiva, about 25. When it’s around 18, that gives the chocolate a very smooth mouthfeel.”

At that point, the beans have been transformed into cacao liqueur, which is put into the conche, a machine that cleans the liqueur by blowing hot air through it. The hot air absorbs acetic and lactic acids and removes them from the chocolate.

The chocolate then rests for two or three weeks, to mellow the flavors before it is melted and molded into bars. “Right now we’re hand scooping nuts and berries into the molds before the chocolate,” Kelsey said. “But we’re going to get a machine to do that.”

After the molds are filled, the chocolates are cooled and then taken to the packaging machine. Packaging is something Kelsey put a lot of thought into. He wanted the bar to be compact and contained, something a bicyclist could tuck into a back pocket. If the chocolate melts, no problem; just rip off a corner of the packaging and drink it rather than eat it.

To stay FDA-compliant, the bars go through a metal detector, and once they’ve passed that hurdle, they’re ready to be packed into cases. Everything is done on site, including roasting nuts for the bars that contain them. “Normally we can produce about 3,000 bars a day,” Kelsey said. “One day, just to see if we could, we made 12,000.”

As for the bars themselves, all of them are 70 percent dark chocolate and dairy-, soy-, and gluten-free, as well as vegan. Some of the bars are designed for people who want chocolate to serve as functional food. One includes pumpkin seeds, protein, cranberries, and guarana (the Endurance bar); another has cranberries, cherries, pomegranate, raspberries, and maca root (the Stamina bar); and the latest creation is the Electrobar, which contains bananas, coconut, coconut water, and Cyprus sea salt to provide some of the electrolytes athletes try to replace via energy drinks. These are hearty, incredibly smooth bars (grinding to 18 microns does make a difference) with a rich, not terribly sweet chocolate. There’s enough flavor and density to any one of them so that a single bar could provide multiple snacks, another reason to feel virtuous about eating them rather than gorging on lower-quality chocolate.

K’ul has also just released a line of single-origin bars: from the Kafupbo co-op in Petit Bourg de Borgne, Haiti, a bar that has a hint of licorice underneath the dark chocolate; from the Hacienda Limon co-op in Los Rios, Ecuador, a delicate, buttery flavor; from the Fazenda Camboa co-op in Bahia, Brazil, a sweet, mild bar; and from Marañón River, Peru, a bar made from Cacao Nacional, a rare, white cacao bean that imparts a strong bitterness along with a hint of butterscotch.

You can find the bars at various retailers around the metro, including the Eastside Co-op, Golden Fig, and Coastal Seafoods. But if you have time, go visit the Franklin Avenue shop. If they have chocolate prepared that day, you can create your own custom chocolate bar, with a line of potential ingredients a lot like you’d see at an ice cream shop. K’ul also offers coffee drinks, but take our advice and pass up the coffee for the sipping chocolate ($3.50). This is basically hot chocolate taken to an exalted level that Nestle’s Quik could only faintly ever dream of. It comes in a small cup. You won’t need much — it’s very rich. But enjoy your sips while waiting for your custom bars to be completed. You’ll be deliriously happy that you did.

K’ul Chocolate

High-quality chocolate energy bars in Seward

2211 E Franklin Ave, Minneapolis

612.344.4300

HOURS:

Tues-Fri 10 a.m.-6 p.m.

Sat 10 a.m.-4 p.m.

Closed Sun-Mon

PARKING: Free lot and street parking