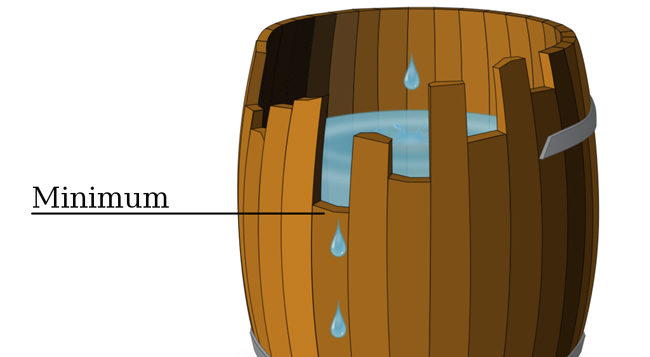

Liebig’s Law states that production is limited by the scarcest resource, despite what other resources are available in abundance. This idea, often illustrated by a barrel with staves of uneven height, is the principle behind St Paul’s latest craft brewery and taproom, Barrel Theory.

Barrel Theory is well on its way to completion in Lowertown and will open in early 2017 adjacent to Dark Horse Bar & Eatery. The head brewer, Timmy Johnson, and the head of operations, Brett Splinter, both come from Surly Brewing Company and are joined by Todd Tibesar, CPA, to form a seasoned team.

We spoke with Splinter about the vision and execution of Barrel Theory, the importance of quality control, and a key-lime Berliner weisse.

HEAVY TABLE: When did the idea for Barrel Theory arise?

BRETT SPLINTER: I’ve wanted to open my own place for about 5 years but only seriously pursued it within the last year or so. I really wanted to have some industry experience and insight before going out on my own.

HEAVY TABLE: Did you always have Timmy Johnson and Todd Tibesar in mind as partners?

SPLINTER: No question — can’t think of two people I’d rather do this with. Todd has been a friend of mine for over 15 years. After he moved back to Minnesota from living out of state, we connected at Firkin Fest and realized we both were into the craft-beer scene. As for Timmy, he and I became friends through the local beer scene years ago. We were both home brewers, and he was working as a pharmacist and making some of the best beers around, in my opinion. After Timmy and I had been working for Surly for a while, we connected with Todd and realized that each of us brought unique and valuable assets to a startup.

HEAVY TABLE: With two of you coming from Surly, how did your experience there shape your vision for Barrel Theory?

SPLINTER: The experience at Surly was really invaluable for many reasons. I think the biggest takeaway is understanding how much of a team effort it really is to run a successful brewing operation that produces real quality. No one channel of the business can really reach a high level of success without the others. There are plenty of breweries that make great beer but struggle with logistics and delivery of the product into the hands of the customer. Conversely, I think there are a lot of breweries that are so marketing-driven it doesn’t really matter how great the beer is as long as the PR push is alive and well.

HEAVY TABLE: The brewery name, Barrel Theory, is based on Liebig’s Law, which states that a barrel can hold only as much water as the shortest stave. Say more about that.

SPLINTER: All three of us are pretty unapologetic in stating that we are beer dorks and have tried a good amount of the beers we’ve sought [to create]. In trying all these beers, we were disappointed that sometimes a brewery can produce an amazing specialty release and have most of their core brands miss the mark considerably. Where is the quality control?

HEAVY TABLE: Meaning that these specialty releases represent the tallest staves of the vessel while the lower-quality beers are the shortest?

SPLINTER: Exactly. There are throwaway choices on these menus. We are not going to put something on tap that we are not proud of.

HEAVY TABLE: Right. It seems that there is high pressure to have a large portfolio, even on opening. To that end, what is your strategy for, or approach to, quality control?

SPLINTER: First of all, it’s ready when it’s ready. There will be days when there isn’t a certain style on, and that’s a good thing. We certainly aren’t saying our beer will be the best out there, but I can commit to us doing our best across the board and never releasing something we don’t feel was properly crafted. Our quality-control philosophy is pretty simple: If the beer isn’t something we are proud of serving to our guests, we will dump it.

HEAVY TABLE: How do you manage people’s expectations, especially with “barrel” in your name?

SPLINTER: Some places only want to make beers that people like, and I hate that. The only expectation we will conform to is high quality. We are not brewing to trends. There is this quote by Steve Jobs that is perfect, something like “people don’t know what they want until you show it to them.” That’s what we will do.

HEAVY TABLE: When it comes to the use of barrels, what are you most excited about?

SPLINTER: We are really excited to get going on barrel-aging right off the bat. There are so many variables involved in the process that it really forces the brewer to ensure the base beer is precisely what he or she wants before sending to age in the barrel. Overall, barrels add an amazing complexity to beer.

HEAVY TABLE: Will barrels be used for sour beer, high-gravity beer, or both?

SPLINTER: We’ll use a variety of barrels eventually but expect virgin oak and wine barrels for sours and mixed fermentation beers, spirits barrels for stouts and other high-gravity ales, and maybe some other surprises as well, like maybe maple.

HEAVY TABLE: Where will you be sourcing barrels?

SPLINTER: They’ll come from a variety of places from Kentucky to California, based on what Timmy is going for.

HEAVY TABLE: What should people know about your brew house and equipment?

SPLINTER: It’s a two-vessel system, made in Michigan from American steel. We went out to take a look at it and got to talk to the guys who did everything, like the welding. We could have gotten a 30-barrel system for the same price, but it’s worth it. The basement cellar will be full of lambic-style racks, which we are able to directly fill downstairs without disturbing the barrels after filling.

HEAVY TABLE: That’s a very small system!

SPLINTER: Yeah. We will be able to turn beers incredibly quickly.

HEAVY TABLE: Any particular beers that you’re looking forward to?

SPLINTER: Timmy makes this sour with key limes, vanilla, and cinnamon… it’s so good. Berliner-weisse-style, but it’s like key lime pie.

HEAVY TABLE: What is your opening plan?

SPLINTER: The brewing system is shrink-wrapped on a pallet, ready to go. The final hurdle will probably be TTB [Alcohol and Tobacco Tax and Trade Bureau] licensing, but we plan to have our first batch in the fermenters by February. But we will be working with our staff before then. I’m excited about our bartenders. We have had so much interest that we basically get to cherry-pick our people.

HEAVY TABLE: Does that make a difference in what people can expect when visiting?

SPLINTER: Definitely. Service is seriously lacking in the local taproom scene, and drinkers are getting smarter. Bartenders at breweries will no longer be able to get away with not knowing ingredients, or how things are made. No beer goes on tap without everyone being trained on it. I mean, training is a never-ending process. How can you say someone is “trained”? That’s like saying a puppy is trained. Here, it never stops.

Nice interview. However I think Mr. Splinter may want to re-think that Jobs quote, particularly in light of his marketing comment above. “People don’t know what they want until you show it to them” is about using marketing to convince people to buy things they don’t need, which I’m sure is not the message BTBC is going for here.

Good point Fred. I was referring more to the aspect of introducing people to styles and flavors they might not have tried before. Certainly not about using marketing to influence them into a purchase they don’t need. And you are right, not the message that was intended.

Fred, that’s not true. Jobs was talking about creating something beyond the mold. Instead of using focus groups to make slight improvements to existing products, he wanted to create something new and innovative. It had nothing to do with advertising or convincing someone to buy something useless.

The analogy is that anyone can make another IPA or Brown Ale that consumers will buy, but I think Barrel Theory wants to set trends and be their own worst critics. In doing so, they have a chance to shape the direction of brewing by leading instead of following.

It’s hard to predict the future, but I think a year from now these guys will be the rising star of the MN brewing scene…

The brewery size discussion had me confused. What is the output volume of the brewing system going to be at startup? Is this going to be a brand that packages for retail to stores and other bars or just draft and growlers to go at their own location?

We have a 10 barrel brewhouse (one barrel = 31 gallons) and 10 and 20 barrel fermentation vessels. Our initial plan is to sell as much beer fresh out of our taproom as possible on draft and in growlers and crowlers. We will have a few local draft accounts in 2017 as well.