There’s a certain kind of cook who, having mastered stir fries and crepes and béchamel and whatnot, starts staring into the fridge and the pantry and the excesses of the grocery list and asking, “What else could I make?” Mayonnaise, though tasty, hardly proves a challenge. Ketchup, it turns out, isn’t worth it.

Inevitably, this restless cook’s eye falls on the cheese drawer: All those dairy products are just milk at the core, right? I could totally do that. And those are the sorts of folks who find their way to Wind Dance Vineyard and order a cheese kit, or two, or three.

Wind Dance’s owner, Bob Belbeck, was once that restless cook, himself. But, first, he was an almost accidental viticulturalist. Finding he had a few spare acres near his home in Delano, MN, he planted grapes and sold the juice to nearby wineries. Thus the vineyard was born. The vineyard became a cheesemaker’s shop about 20 years ago when Belbeck started experimenting with cheese and found it hard to buy supplies in small amounts. He started selling kits online and in a few select stores and now has a line of kits for six kinds of cheese, along with presses, molds, and cultures.

Belbeck says he can usually tell who is going to turn into a regular customer. These are the folks whose first order is the Parmesan kit (most people, wary of the aging process or looking for a quick cheese fix, go for the mozzarella). Parmesan is Belbeck’s favorite and, he says, the easiest to start with because it calls for two-percent milk (when making cheese with two-percent, Belbeck says he can buy any old milk off the shelf, but finding a whole milk that will work is trickier). Then, about six months after that first order — meaning immediately after that customer has had his or her first taste of homemade Parmesan — he gets another order. They’re hooked.

“All of our [store-bought] cheeses now taste processed, once you tasted real cheese. It’s like wine: If you’re going to have it, you might as well have some of the good stuff,” Belbeck says. He now makes nearly all the cheese he and his wife eat. “Good Parmesan costs $18 a pound. I can make two pounds for $8 or $10 and it tastes better. A lot of the Parmesan in the store doesn’t taste like it’s aged at all.”

Beyond making cheese, Belbeck loves to talk cheese. He forwards the phone number listed on his website to his cell phone when he’s not in his office and encourages customers to call with questions. “Somebody called last week while he was making the cheese and it wasn’t working out,” he says. “We were on the phone quite a long time and I was tempted to just drive over there. But it turned out he was using ultrapasteurized milk. I sent him a new kit for free and told him to try it with powdered milk and it worked great.” (See Belbeck’s cheese FAQ here.)

The invitation to call and talk cheese any time does come with one small request: “Especially Friday and Saturday nights when people are drinking wine and making cheese, I’d prefer if they called before they drank the whole bottle of wine,” Belbeck says.

I’ve also been that restless cook, staring at the groceries and wondering how I could pare them down to their base ingredients. I’ve tried my hand at mozzarella, paneer, and ricotta. Homemade yogurt and I are good friends. But the process of aging cheese intimidated me: all those unchecked bacteria, that months-long wait to find out if I’ve made a grave (read: either deadly or disgusting) error. But the kitchen tinkerer’s urge is a strong one, and on a recent trip to EggPlant Urban Farm Supply in St. Paul, I heard a Wind Dance Vineyards cheddar kit calling out to me, along with the familiar refrain: “It’s milk plus bacteria. How hard could it be?”

At EggPlant, owner Audrey Matson looked me up and down and said, “You’re not going to use, you know, skim for this, are you?” (Do I give off skim sort of vibes? I guess so.) Skim is out of the question, it should go without saying. Cheese is tasty bacteria + fat. She recommended Cedar Summit milk, which is not homogenized, not ultrapasteurized, and is local and organic to boot.

The kit put me back $7.50. Along with two gallons of Cedar Summit milk totaling $20, my cheddar would come out at about $14 a pound. Well, that plus about three hours of labor. A premium price, but not out of line with what I hoped would be the quality of the final product.

- Tricia Cornell / Heavy Table

Other than the starter, rennet, and cheese salt that come in the kit, you’ve probably got most of what you need to make cheese right in your kitchen: a 2.5-gallon pot, a long spoon, a long knife, a thermometer, and a colander. The big challenges are the press and the mold, which I’ll get to later.

A few equipment notes: A 2.5-gallon pot is a very big pot. It’s bigger than your average stockpot or Dutch oven, so I used my canning pot. I switched from my candy thermometer to an electronic one with a long probe because I liked the greater precision and because I could keep it in the pot while the lid was on. And I used my own cheesecloth for draining the curd, since the small square provided looked entirely inadequate to the task.

Belbeck’s instructions are remarkably easy to follow, clearly written by someone who learned cheesemaking through trial and error and knows how to explain what you’re looking for and what might be a bad sign. When my milk set up in a glorious custardy curd, I looked around, hoping to find someone to high-five in my empty kitchen. After the curd sets, there isn’t much more that can go wrong.

After the salting and the draining, however, comes the pressing. The final step before aging is to place the cheese under 50 pounds of weight for 12 hours, to press out the last of the liquid and set the curds into one tight block. I had bought a kit without a mold (kits with a mold are available online for about $1 more) and I haven’t invested in a press (yet).

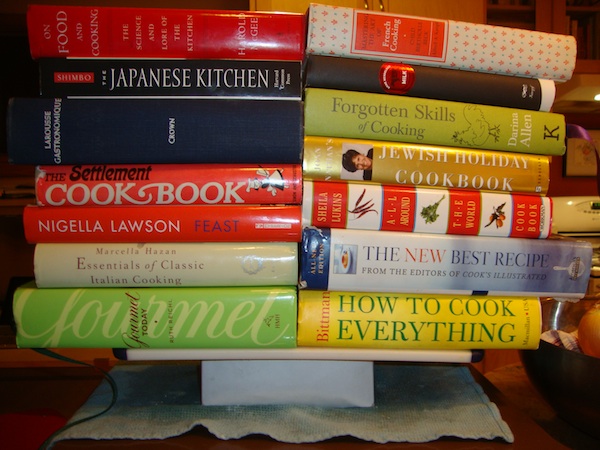

I tried jerry-rigging a pile of kitchen equipment on top of my precious handful of curds in a colander, but I had a feeling I wouldn’t be happy with the shape, and I was more than certain I would wake up to the clatter of a kitchen avalanche. My eye then fell on the box the kit came in: exactly the same size as a two-pound block of cheese. I packed the curds in and piled on the heaviest cookbooks I could find. Within an hour, the cardboard box was soaked with whey and nearly collapsed, so my cheese block won’t have nice crisp corners. But it will be thoroughly pressed. Belbeck says he has an inexpensive cheese press in the works, one he might be able to retail for $20 or $30. In a few months, after I’ve had my first taste of homemade cheddar, I might be lining up to be one of the first buyers — right after I place my order for a Parmesan kit.

Excellent – I’m a cook whose motto is “How hard can it be?” so cheese-making has been on the list for a while (after having tackled ricotta & yogurt in the milk category). I’ll have to disagree on the ketchup though – it’s so amazing made from scratch! To me, it’s in an entirely different category from what you buy in the store. And don’t get me started on bacon. That’s delicious. I’ve also been pondering prosciutto, but I’m also concerned about the “grave” errors… Thanks for the great article & nudge!

Love making my own cheese – especially with Cedar Summit milk. Been making ricotta and mozzarella – both way better than anything I’ve gotten at the store.

This sounds so tempting. Noever tried it before but I’m putting it on my “to do” list!

oh wow, totally missed this. I just started trying my hand at cheesemaking, too. I saw the Vineyards but started out with Rikki Caroll’s site and book since that seems to be the traditional path. I’ve had some good and some bad so far — disastrous chevre, perfect 30 minute mozz to work on technique, yummy buttermilk cheese with herbs.

http://themartys.wordpress.com/2011/02/15/if-at-first-you-dont-succeed-try-mozzarella/

today I get my first batch of real cultures so I can make some mother cultures and some more complicated cheeses. and I’ve been running around the house trying to put different coffee cans, tupperwares, etc together to make my own cheese press, which I think I can now do with a big folgers can, a mediu sized thermos and some free weights.

Here’s an easy do it yourself press I’m tempted to try. I would *kill* for a 20-30 dollar press. The best I’ve seen price wise so far is at midwest brewery for 65 dollars.

http://biology.clc.uc.edu/fankhauser/Cheese/Cheese_5_gallons/Cheese_press/PRESS_SETUP_00.htm